On-demand Nitrogen and Oxygen Generators

On-Site Gas Systems proven Nitrogen & Oxygen PSA and membrane technology offers customers rapid returns on investment and stable year-to-year gas costs. Offering Nitrogen and Oxygen purities of 95-99.9995% and generating volumes in excess of 990 m³/hr, these units provide unsurpassed levels of performance. Low operating pressures increases system safety, and eliminates the need for hazardous storage.

With rising energy costs, the ROI is better than ever! On Site’s proven Nitrogen and Oxygen PSA Generator technology gives you quick returns on your investment and stable year-to-year gas costs.

Nitrogen abd Oxygen membrane generators are complete turn-key systems. They can be built to your specifications, and we can match our generators to your compression equipment for any application. On Site systems offer proven performance that is both cost-efficient and flexible, and you’ll find us in some of the most demanding environments in the world.

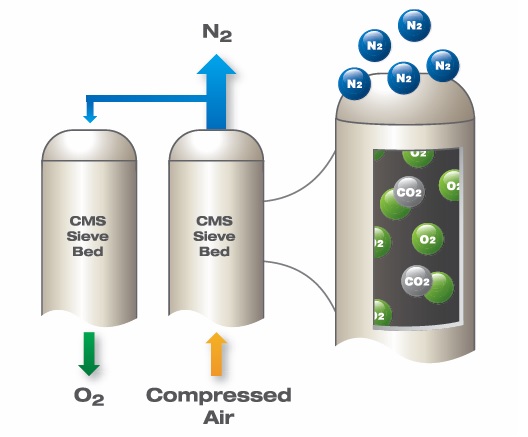

How it works - PSA

These are PSA (Pressure Swing Adsorption — you read correctly — it’s ad-, not ab-) nitrogen generating systems. Purity from 95-99.9995%, flow lab to 35,000 SCFH. Each unit has two adsorber beds filled with a carbon molecular sieve (CMS). Compressed air enters one end of a bed. While the smaller oxygen molecules are adsorbed by the CMS, the larger nitrogen molecules pass through the sieve and are stored. Once the tube is saturated with oxygen, the first adsorber releases the gas, and the second adsorber starts the process over again.

Membrane

Compressed air enters one end of a permeable membrane. The membrane is comprised of many hollow fibres. The nitrogen in the compressed air travels the length of the fibres, and exits at the other end of the membrane. The oxygen in the air passes through the sidewall of the fibres and exits through the sides of the membrane. This is textbook continuous flow, with no moving parts!

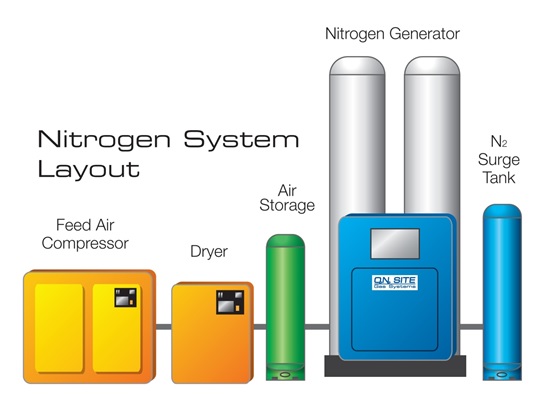

Typical Generator Layout

INTECH Power Service provide application support and development of a solution which includes the local supply of receiving tanks, compressors, pressure boosters and skid mount solutions as required.

Our team of support engineers build and test the solutions/systems in our Moreton-in-Marsh facility prior to commissioning on site. The integrated skid mount solution means a tested plug and play solution when delivered

INT Skid mounted N-75 with receiving tank

INT Skid mounted N-30 with receiving and dedicated compressor

Get in touch

Complete your details and we will call you back.